Science Energy -India Private Limited

A Breakthrough Technology,

100% Green Digital Electrical Energy

in JV with Science Golden

2. Compact, Intelligent, Revolutionary: Comes in 10/20 Feet Containers and delivers one MW/Hr. 24X7 X 1,00,000 Hrs. Warranty

3. Zero Capital Investment by the Client, Client signs a long term PPA and pays for Electricity.

4. Up to 30% cheaper than your grid electricity costs

5. Digital Power: Equalization, Harmonic Curves, Perfect cycling and Reactance, Digital Transformer.

6. Delivery at the Appropriate Voltage and cycling for demand

7. Improves Life of your Equipment with the Quality of power supplied to run it.

The Concept

Also called PSH –Power Storage Hydroelectric. It produces hydrokinetic flow, of high density, pressure and speed, in a shielded and sealed system, converted into mechanical energy and later, into electrical through synchronous generators of high efficiency, converted into digital energy, in a continuous cycle, without loss of fluid.

The Processes

-

Flow production

Flow production

-

Conversion of kinetic energy into mechanical

Conversion of kinetic energy into mechanical

-

Conversion of mechanical energy into electrical

Conversion of mechanical energy into electrical

-

Conversion of analog energy into digital

Conversion of analog energy into digital

-

Digital transformation of voltage

Digital transformation of voltage

-

Passage reservoir

Passage reservoir

-

Air conditioning in 22 degrees centigrade

Air conditioning in 22 degrees centigrade

-

Pressurization at sea level

Pressurization at sea level

-

Power supply and conservation of energy by intelligent batteries

Power supply and conservation of energy by intelligent batteries

-

Satellite communication system

Satellite communication system

-

Anti-fire system

Anti-fire system

-

Redundancy system

Redundancy system

Kinetic Energy

Conversion of Kinetic Energy into Mechanical Energy

includes four motor pumps, in parallel, with three in operation and one in standby, in rotation, with each pump operating 240 days and resting 120, moving 30 litres per second, 108 cubic meters per hour, at gauge height greater than 66 MCA, at a pressure of 16 BAR, with acceleration exceeding 236.7 km per hour, generating 54,000 joules per second, 5,506.4 KGF, 5.5 tons per second. The kinetic energy is converted by dynamic turbo rotor, by direct coupling to the generator shaft through vacuum.

Conversion of Mechanical Energy into Electrical Energy

Digitization of Analog Energy into Digital Energy

Climatization of The Compact Containerized System

Pressurization ensures permanent atmospheric pressure at sea level, ensuring the operation of the system at any altitude, without loss of efficiency.

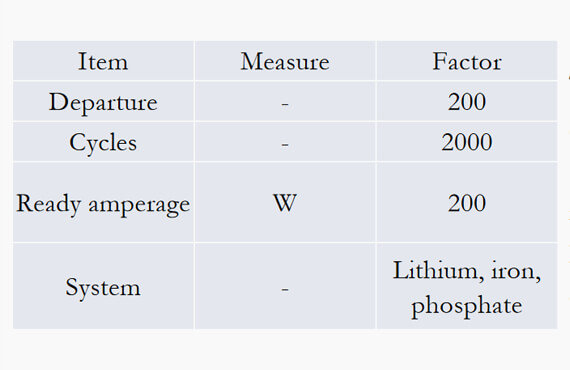

Smart Battery Management System

exchanged and recycled by the manufacturer, without any damage to the environment.

Fire Prevention System

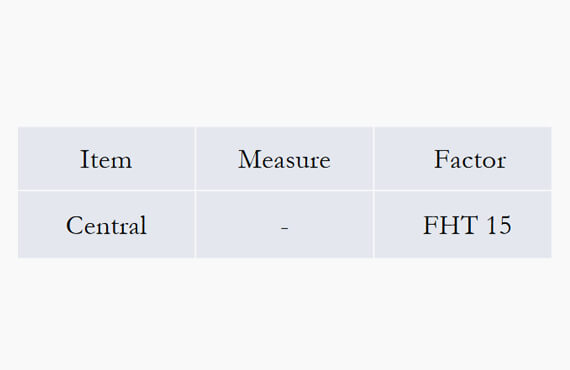

Real Time Monitoring

anywhere on the planet.

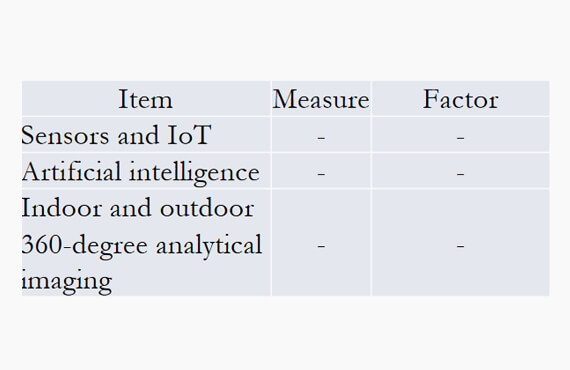

The Smart Grid Power, SGP 1,000, operates in redundancy, controlled by sensors and IoT, artificial intelligence, in real time. It provides a

total guarantee for 100 thousand hours, guaranteeing the enjoyment of energy.

Technical Specifications

Container

flat and dry. It is installed on vibrastop, leveled and fixed. Allows aerial or underground cabling up to a maximum of 5 km. Allows stacking up to 4 units (in special cases). It is recommended to distance 1250 mm from each other.

Power Delivery

Flow Production

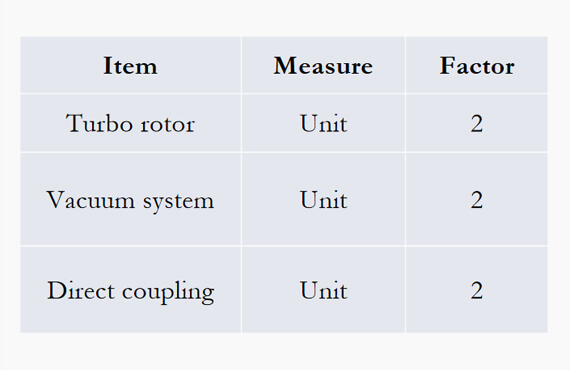

Dynamic Turbo Rotor

They transfer 1,800 rpm to the generator shafts.

Synchronous Generators

Digital Processing

Communication of Data

it operates in redundancy.

Data Storage

Passage Reservoir

Smart Batteries

Climate Control

Pressurization

Fire Prevention System

Predictive and Preventive Maintenance System

The System has been tested for all Countries electricity parameter compatibility.

Contact us

16th Floor, World Trade Tower, Tower B, Sector 16, Noida 20101, India.