Mass Scale H2 Production Technology Details

Making India Net Carbon Negative

With “H2G” The Breakthrough in

Green Hydrogen Technology

Solarin Solar Power Solutions PVT LTD (Solarin)

About Solarin’s Mass Scale H2 Technologies

splits HHO Bonds using very little Electrical energy and using Magnetism and Resonance to break the HHO Bond.

Why Focus on Hydrogen?

Because Hydrogen will replace most Fossil Fuels in future

Why H2G?

“H2G” Hydrogen Generator

Comparative Analysis of Carbonless Technology

Electrolysis

| 01 | 18 – 20 Kg of Hydrogen generation / MW of Electrical energy consumption |

|---|---|

| 02 | 30 to 40 KWh Energy required / KG of Hydrogen generation |

H2G

| 01 | 200 Kg of Hydrogen generation / MW of Electrical Energy consumption |

|---|---|

| 02 | 5 KWh Energy required / Kg of Hydrogen Generation |

Secret of

The Breakthrough

Success

The science has been proven and published in international professional journals. Prototype has been made and the complex combined effect in its Hydrogen Generator H2G Product is being packaged for Pilot plant of 100 to 400Kg/Hr. Capacity.

Independent Scientific Researcher

Prove Magnetism doubles Hydrogen Extraction

Aligning the spin states of oxygen intermediates overcomes a bottleneck in electrolysis

by Mark Peplow, special to C&EN

JUNE 14, 2019

Abstract: Using nothing more than a magnet, researchers have doubled the hydrogen output of a water-splitting electrolyzer (Nat. Energy 2019, DOI: 10.1038/s41560-019-0404-4). If the approach can be scaled up, it has the potential to slash the costs of producing hydrogen from water, making the clean-burning fuel greener.

Independent Scientific researchers

Prove Effect of Irradiation

Noriah Bidin 1 , Siti Noraiza A Razak 1 , Siti Radiana Azni 1 , Waskito Nguroho1,2 , Ali Kamel Mohsin 1 , Mundzir Abdullah1 , Ganesan Krishnan 1 and Hazri Bakhtiar 1 April 2014 Laser

Physics Letters 11(6):066001

DOI: 10.1088/1612-2011/11/6/066001

Abstract

The effect of green laser irradiation on hydrogen production via water electrolysis was investigated. Diode pumped solid-state laser operating in second harmonic generation was employed as a source of irradiation. The hydrogen production system was also irradiated by a conventional light, a halogen source, for comparison. The best catalyst was identified by mixing distilled water with two types of salt: NaCl and Na 2 SO 4 . Optimization of hydrogen production from water electrolysis was realized by using NaCl and green laser irradiation. The power of green laser irradiation and the concentration of NaCl in water contribute to hydrogen production. The hydrogen yield also depends on the distance and direction of the green beam to the electrode

Independent Scientific researchers

Prove Combine Effect of Magnetism and Irradiation

Noriah Bidin Siti Radhiana Azni Shumaila Islam Mundzir Abdullah M. Fakaruddin Sidi Ahmad Ganesan Krishnan A. Rahman Johari M. Aizat A. Bakar Nur Syahirah Sahidan Nur Fatin Musa M. Farizuddin Salebi Naqiuddin Razali Mohd Marsin Sanagi International Journal of Hydrogen Energy Volume 42, Issue 26, 29 June 2017, Pages 16325-16332

Abstract

Hydrogen production via water electrolysis was studied under the effect of magnetic and optical field.

As a result hydrogen production due to magnetic field is higher in comparison to optical field. However the combination both fields have generated superior effect whereby the hydrogen yields Nine times higher in comparison to conventional water electrolysis.

Current Stage of H2G

being Packaged for Pilot Project

Prototype Results

Hydrogen will completely replace Fossil Fuel in future The market size of Fossil Fuel can be equated to the market size of Hydrogen with many applications

Indusrial Power Plant Conversion

Can Minimize / Eliminate 30% of our total fossil fuel import

Grid power with W2H2 Gen Sets. This setup is proposed in the demonstration and Validation Application

W2H2 cheap hydrogen production has many advantages:

1. Replace Fossil Fuel

2. Reduce Pollution

3. Reduce Energy costs thus make Indian Industry competitive in International market.

Auto Sector

(H2G Can Replace 50% of India’s Fossil Fuel Import)

1. Hydrogen Filling stations: Is an Established concept

2. High cost of Hydrogen is the Primary impeding Factor

3. H2G Advantages is Low cost and On-Site generation

4. Transition to Fuel Cell: Retrofit Kits can save 30 to 50% with

dual fuel use.

Can Impact 50% of India’s total Import of Fossil Fuel Plus a New Industry will be Born Creating Jobs

Solarin JV Scientists have developed Adaptors that can convert Internal Combustion Engines to run 100% on H2. 2 Years of trial has been conducted on a 500 KVA Engine

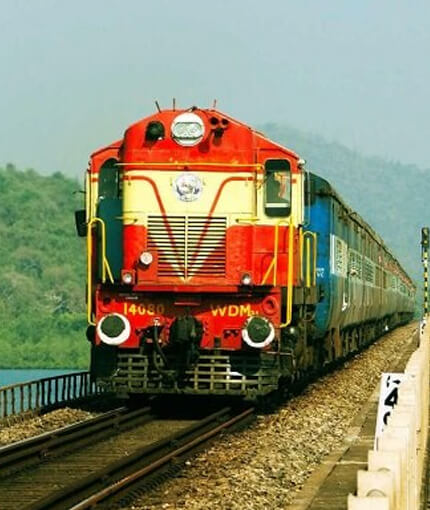

Indian Railways

H2G is tested in running Internal Combustion Diesel Engines with H2G generated Hydrogen.

Diesel Engines can be retrofitted to run 100% on Hydrogen Saving 30 Lakhs Liters of Diesel every year. A proposal will be submitted to the Railway inistry for conversion of all Diesel Engines into 100% H2 Engines

Industrial Raw material and Cost Reduction

Many Industrial Products require high volume of Hydrogen

• Methanol Production

• Hydrogenating Agent

• Refineries

• Metallic Ores

• Chemical Production: Alkali production, HCL and many

Low-Cost Hydrogen can have multitude of beneficial effects in the economy

H2G System Technologies

Solarin JV H2G system technologies can make use of following applications

2. Converting Internal Combustion Engines into 100% H2 use engines. Very useful for Rail Engines. Three Years Trial has been done on IVECO Model 13 engines. It is very similar to the Rail Engines. If provided with proper infrastructure Solarin JV can convert 10 Engines pr day to H2 Engines.

3. Use of H2 in Oven in Ceramic Industry

4. Mass scale H2 Generation (Up to 1 Ton/Hr.) for use in industries where H2 is the raw material.

Contact us

16th Floor, World Trade Tower, Tower B, Sector 16, Noida 20101, India.